Williams Building Group Ohio

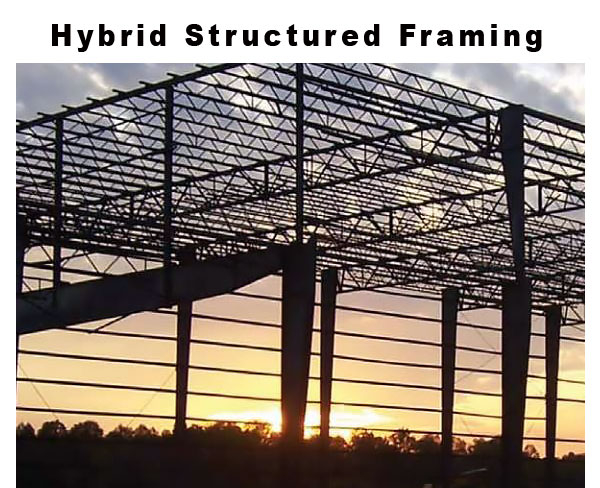

Hybrid Structures

Hybrid projects are defined by their need for a tall structure, long span capabilities, and specific heavy design load requirements. Each Hybrid Construction project is evaluated on an individual basis to determine the most economical and efficient solution.

- A proven standing seam metal roof (SSR) or metal wall system by the Williams Building Group offers long term weather protection with minimal maintenance and low life cycle cost

- Conventional steel laced columns improve strength for increased load capacity

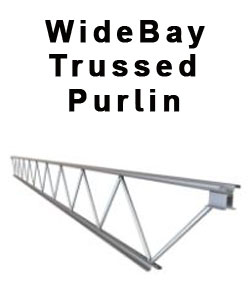

- Pre-engineered steel framing system on top of conventional steel columns advances material efficiency and reduces overall project costs and erection time

When compared to conventional structural steel construction, Hybrid Structures offers the opportunity to create the most efficient design possible. That’s because hybrid construction utilizes the efficient design practices of the Williams Building Group's pre-engineered systems combined with available structural steel shapes. Historically, the pre-engineered industry has utilized 3-plate fabricated members to meet the exact design requirements that facilitate the functional needs of a project. With the hybrid design concept, our buildings takes the same approach with all steel elements to optimize the steel used in the building. This approach minimizes the overall cost of the building material required to fulfill the functional needs of each project. In addition to minimizing the cost of the building, we can also minimize the erection time required on the site because many complete assemblies are pre fabricated. This also saves erection labor costs and allows for earlier occupancy, resulting in additional income for the end user.